Timely and qualified services will be provided to our esteemed customers.

TECHNICAL REACTION:

Such as: Acetylation Chlorination, Epoxidation, Acylation, Crystallization, Esterification, Alkylation, Cyclization, Halogenation, Brominating, Dealkylation Halide Exchange, Carbomethylation, Decarboxylation, Hoffman reaction, Oxidation, Phosgenation, Process Optimization, Reduction, Resolution of racemes, Tosylation, Phase transfer reaction ......

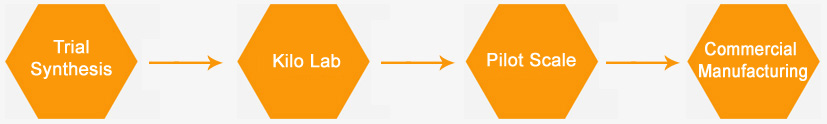

PROCESS DEVELOPMENT: We continually improve our facilities, upgrade equipment and develop & refine novel techniques toward optimal quality and cost efficiency.

We continually improve our facilities, upgrade equipment and develop & refine novel techniques toward optimal quality and cost efficiency.

Multiple reactor sizes ranging from 50 to 2000 L

Agitated pressure filters, centrifuges and notches

acid and alkaline resistant equipment

Temperature ranging from - 80°C to 250°C

Pressure ranging from 2mbar to 40 bar

Finish product handling/ drying in controlled areas

Quality assurance through the systematically analytic process is the key to our success. In-process and final quality control are performed under the following devices:

Certification of analytical reference standards via full chemical analysis

NMR Analysis

Mass Spectrometry Analysis

IR Analysis

GC/MS, HPLC/MS/MS

Water Content by Karl Fischer

Optical Rotation

Isolation and characterization of impurities and degradation products

We work according to the quality management systems of GMP and ISO 9001:2008,have the documentation includes BPR/SOP/DATA AUTOMATION/COA/SDS, understand the GMP requirements and can supply desired quality material at competitive price with all documents support