1. Lab development of new molecules, trail synthesis and pilot scale up.

Route of Synthesis: Synthetic Route Design、Assessment and Development

Process Research and Development:

Process Optimization for improving yield and reducing the cost;

2. commercial production at qualified plant:

Our two production sites are all certified with ISO9001 and ISO14001 system. One focus on R&D, process optimization, technical innovation and scale up production; another multifunctional plant works on commercial manufacture according to GMP guidelines.

We continually improve our facilities, upgrade equipment and develop & refine novel techniques toward optimal quality and cost efficiency.

Multiple reactor sizes ranging from 50 to 2000 L

Agitated pressure filters, centrifuges and notches

acid and alkaline resistant equipment

Temperature ranging from - 80°C to 250°C

Pressure ranging from 2mbar to 40 bar

Finish product handling/ drying in controlled areas

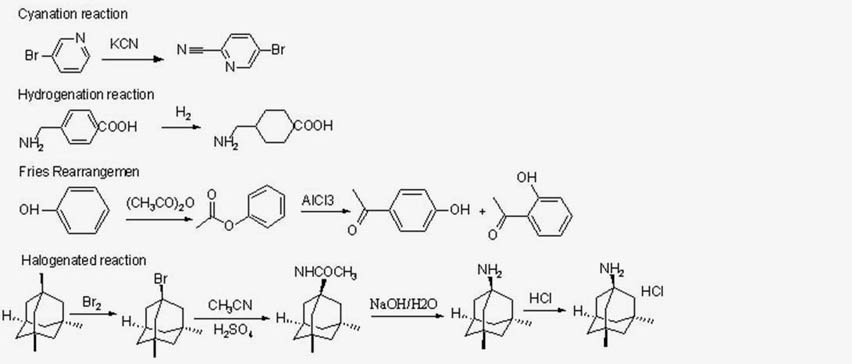

TECHNICAL REACTION:

Acetylation Chlorination Epoxidation

Acylation Crystallization Esterification

Alkylation Cyclization Halogenation

Brominating Dealkylation Halide Exchange

Carbomethylation Decarboxylation Hoffman reaction

Oxidation Phosgenation Process Optimization

Reduction Resolution of racemes Tosylation

Phase transfer reaction ......

3. Strictly confidential agreement on Products, Technical, Process etc. every scope.

3. Strictly confidential agreement on Products, Technical, Process etc. every scope.

4. Experienced and dedicated chemical engineers;

5. Under confidential agreement, below docs for vendor qualification and GMP/DMF filings for your API -

Route of synthesis with solvents, reagents, raw materials and catalyst data used in each stage;

Flowchart with solvents, reagents, raw materials and catalyst data used in each stage;

List of solvents, reagents, raw materials and catalyst data used in each stage;

Brief manufacturing process;

Product Advantange

1. Competitive price

2. Excellent quality:

Quality assurance through the systematically analytic process is the key to our success. In-process and final quality control are performed under the following devices:

Certification of analytical reference standards via full chemical analysis

NMR Analysis

Mass Spectrometry Analysis

IR Analysis

GC/MS, HPLC/MS/MS

Water Content by Karl Fischer

Optical Rotation

Isolation and characterization of impurities and degradation products

3. Ontime Delivery

Well package to ensure different property chemicals under appropriate conditions during storage and transporting.

Professional logistics and transportation services to insure the quickly, safety and on-time delivery.